Phillips Saw & Tool is a certified weld center for bandsaw blades. Over 50 years of experience and large financial investments allow automated CTL (Cut To Length) machines to provide consistent weld and anneal zones, ensuring quality and dependability. Partnering with ALO Teknik, we custom designed the newest ALO 177 CTL machine to enable weld centers more flexibility and productivity. Below we have highlighted three key components to our ever growing weld center: Advanced Laser Measuring, High Production Capacity and Dependable Welds. We currently offer welded to length band saw blades for distributors and end users.

We only distribute the highest performing blades: Amada, Wikus, Bahco, Lenox, Roentgen, Arntz and Freedom. We believe each manufacturer offers a great performing band for certain / specific applications. No matter the customer, we stand behind our weld / anneal zones 100% and guarantee performance every time or we will make it right. Depending on location and frequency of servicing, pick-up & delivery routes are available. If this option is not applicable, welded bands can ship domestic and international. Responsive Services have allowed PSAWS to gain marketshare by exceeding customer expectations and furthering relations between manufacturer and end user. Contact us if you are searching for a focused, accessible, specialized welder for your band saw operations.

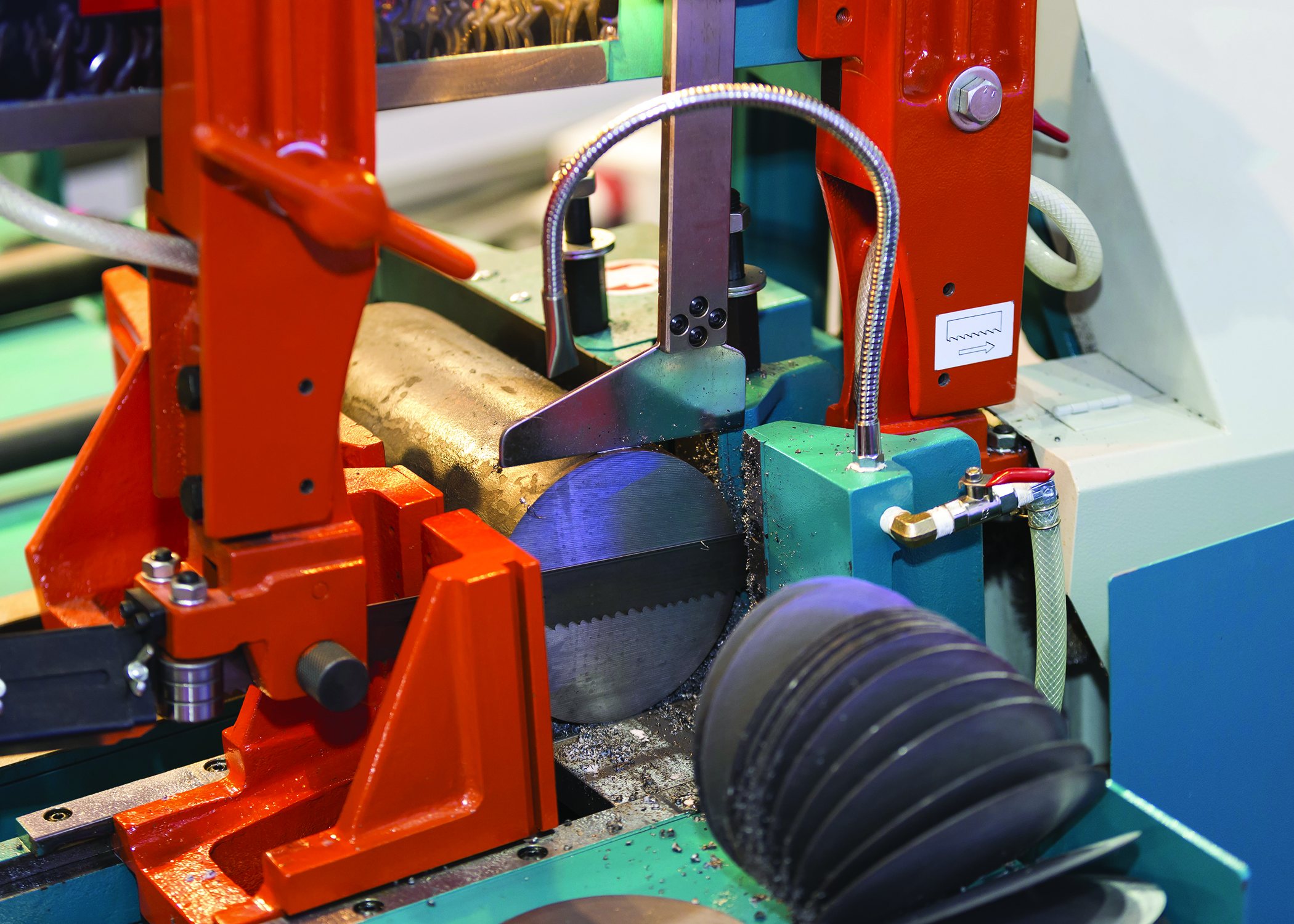

FERROUS

FAST CUTTING / EXCEPTIONAL FINISH is achieved combining high cutting speeds with the fine cut finish of cold sawing. Cermet’s self-sharpening wear pattern keeps cutting forces low even after long periods in cut, resulting in mirrored smooth surfaces.

NONFERROUS

COMPLEX EXTRUSIONS / THIN KERF blades are 20% thinner than conventional saw blades, providing tremendous material savings and reduction of recycling costs. A thinner kerf creates clean cuts, reduced harmonics and increased production.

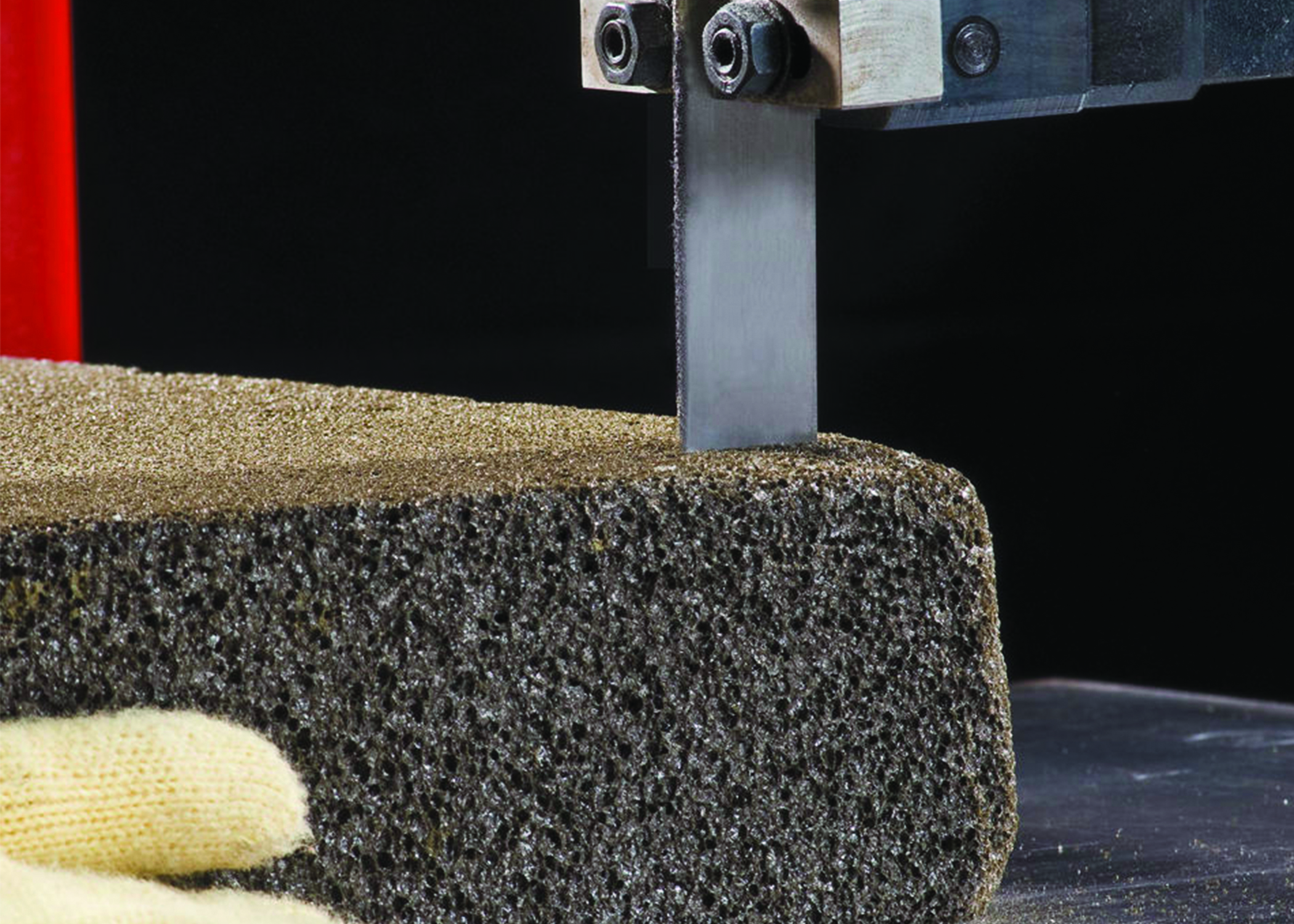

WOOD

HEAVY RIP SAWING / CUSTOM DESIGN flat

INDUSTRIAL DEMANDS / UNPRECEDENTED PRODUCTION from blades designed

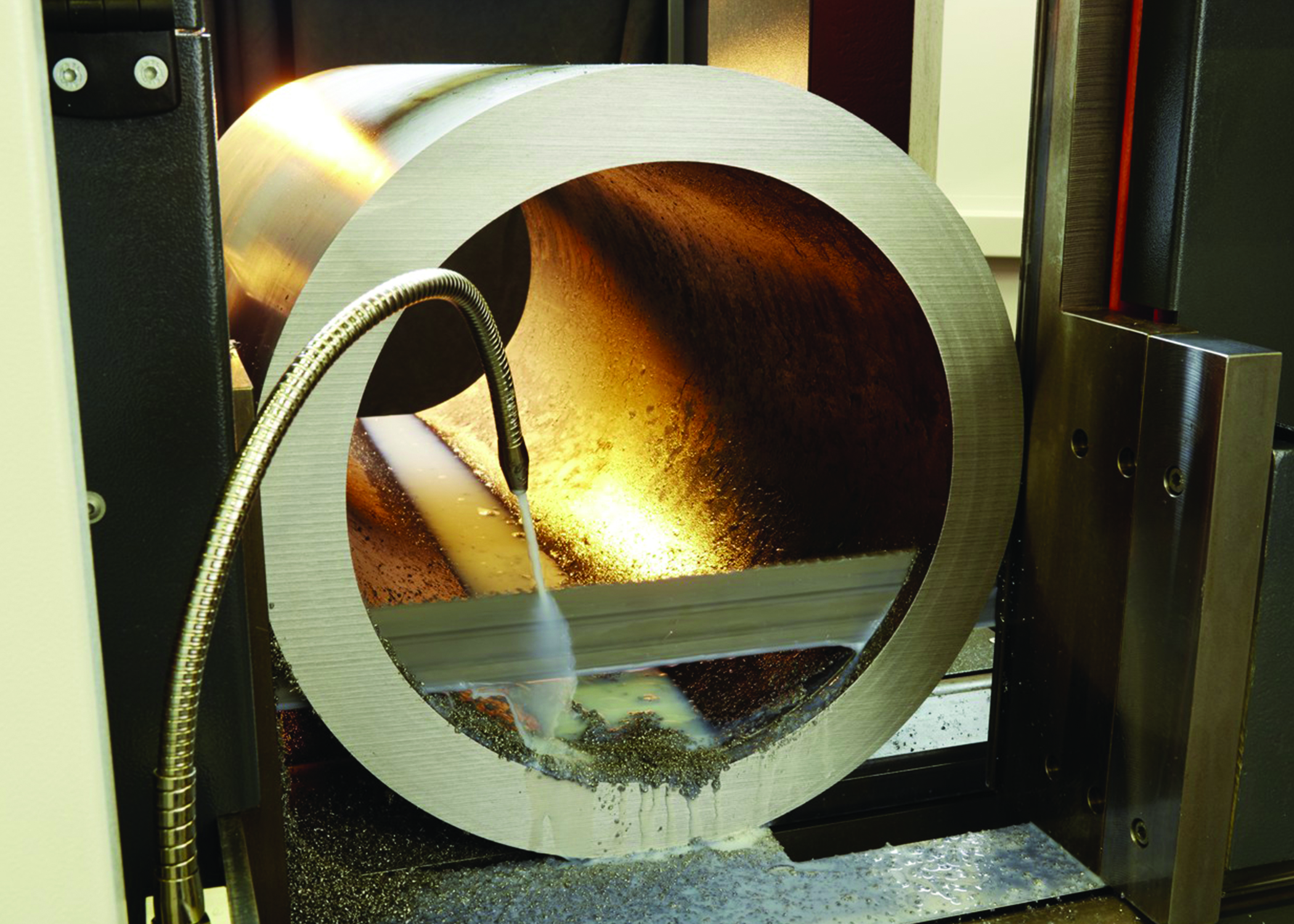

INDUSTRIAL DEMANDS / UNPRECEDENTED PRODUCTION from blades designed specificially for high output operations. Single or Twin machines cutting no, minimal or large ID-scarf. Cutting speeds: 80 - 600 m/min. Common Machines: Rattunde, Mair, MTM, RSA, OTO Mills, Adige, Nakata and Olympia.

INDUSTRIAL DEMANDS / UNPRECEDENTED PRODUCTION from blades designed specificially for high output operations. Single or Twin machines cutting no, minimal or large ID-scarf. Cutting speeds: 80 - 600 m/min. Common Machines: Rattunde, Mair, MTM, RSA, OTO Mills, Adige, Nakata and Olympia.

INDUSTRIAL DEMANDS / UNPRECEDENTED PRODUCTION from blades designed specificially for high output operations. Single or Twin machines cutting no, minimal or large ID-scarf. Cutting speeds: 80 - 600 m/min. Common Machines: Rattunde, Mair, MTM, RSA, OTO Mills, Adige, Nakata and Olympia.

VERSATILITY WITHIN HIGH STRESS OPERATIONS through blades developed for heavy cutting creating mechanical stress and high operating temperatures. Our blades provide flexibility among material specs & cutting parameters. Common shapes: steel pipes, tubes, sections & rails.

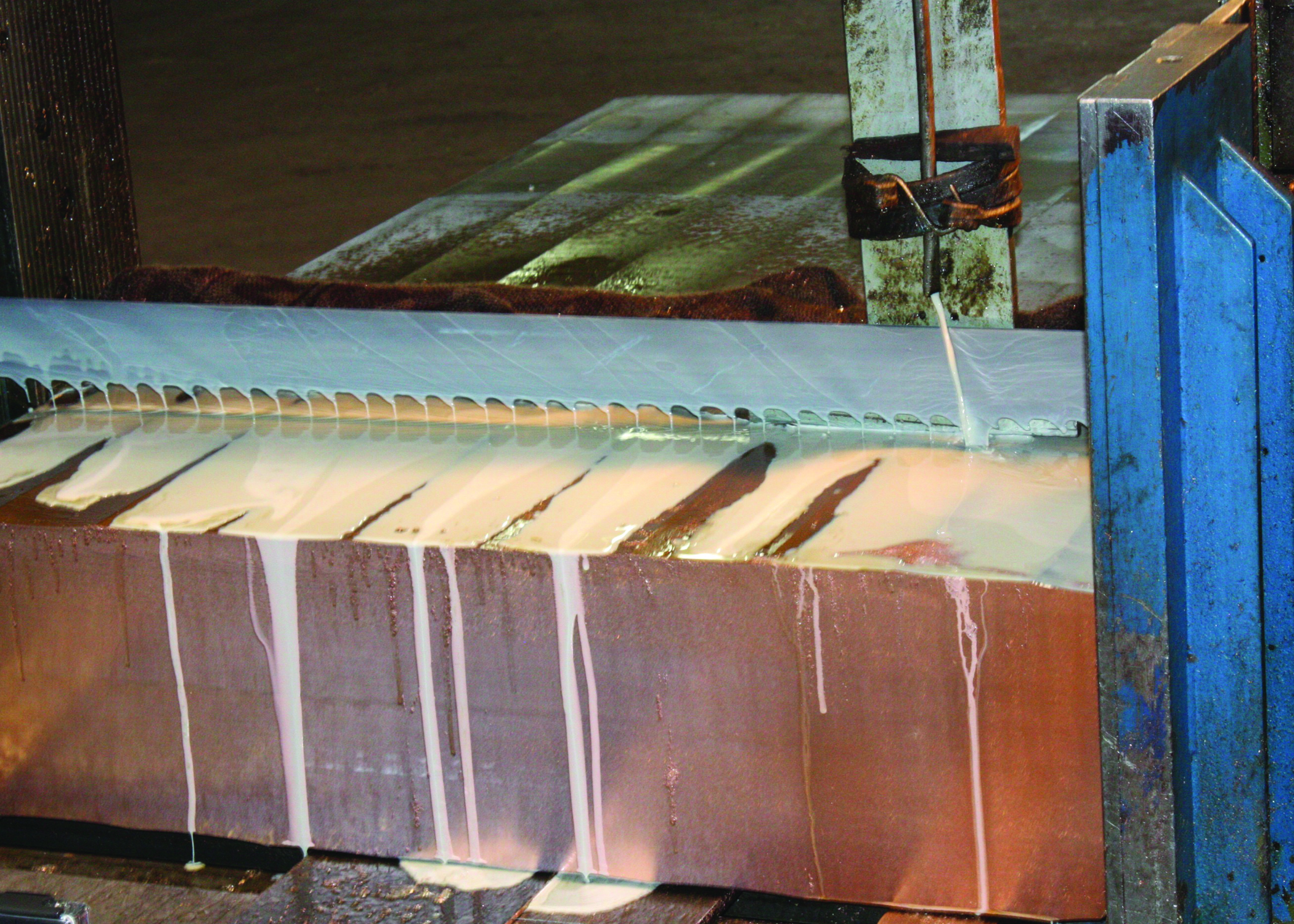

NONFERROUS

COMPLEX EXTRUSIONS / THIN KERF blades are 20% thinner than conventional saw blades, providing tremendous material savings and reduction of recycling costs. A thinner kerf creates clean cuts, reduced harmonics and increased production.

SIMPLIFY OPERATIONS / ADVANCED CARBIDE makes cutting all types of non-ferrous metal simple and easy. Specially formulated teeth retain extremely sharp edges, extending tool life and maintaining consistent chip removal. Operations can simplify cutting of plate, extrusion and solid material.

STRAIGHT CUTS IN LARGE SOLIDS is possible by incorporating heavier gauge steel plates used to withstand rigors associated with sawing larger dimensional pieces. Incorporating appropriate side clearance and relief geometries provide straight, consistent cutting.

WOOD

HEAVY RIP SAWING / CUSTOM DESIGN flat tensioned plates enable truer run-out for smoother finish and exact dimensions. Specific designs utilize inside and outside wipers, manufactured according to customer’s application and requirements.

CROSS CUTTING / INCREASE YIELD applying a thinner kerf, enabling tremendous increases while making less cutting pressure for very clean cuts. Laser slit designs allow reduced plate thickness without compromising lateral stiffness. Blades will produce less swarf operating at extreme cycle times.

HIGH OUTPUT / EXCEPTIONAL QUALITY that outlasts conventional saw blades up to 2 times. This is possible utilizing: straight / tensioned plates, vibration dampening slits, exotic carbide grades and advanced coatings. Common materials: veneer, melamine, HPL, MDF and HDF.